Activated Carbon Manufacturing Solution using Waste Plastics

Eco-Friendly Activated Carbon and Manufacturing Equipment Using Superheated Steam

Powdered Activated Carbon and Manufacturing Equipment Produced by Pyrolyzing and Activating Residues from the Waste-Plastic Liquefaction Process Using Superheated Steam at 900°C or Higher

Features of Performance on Manufactured Activated Carbon and Equipment

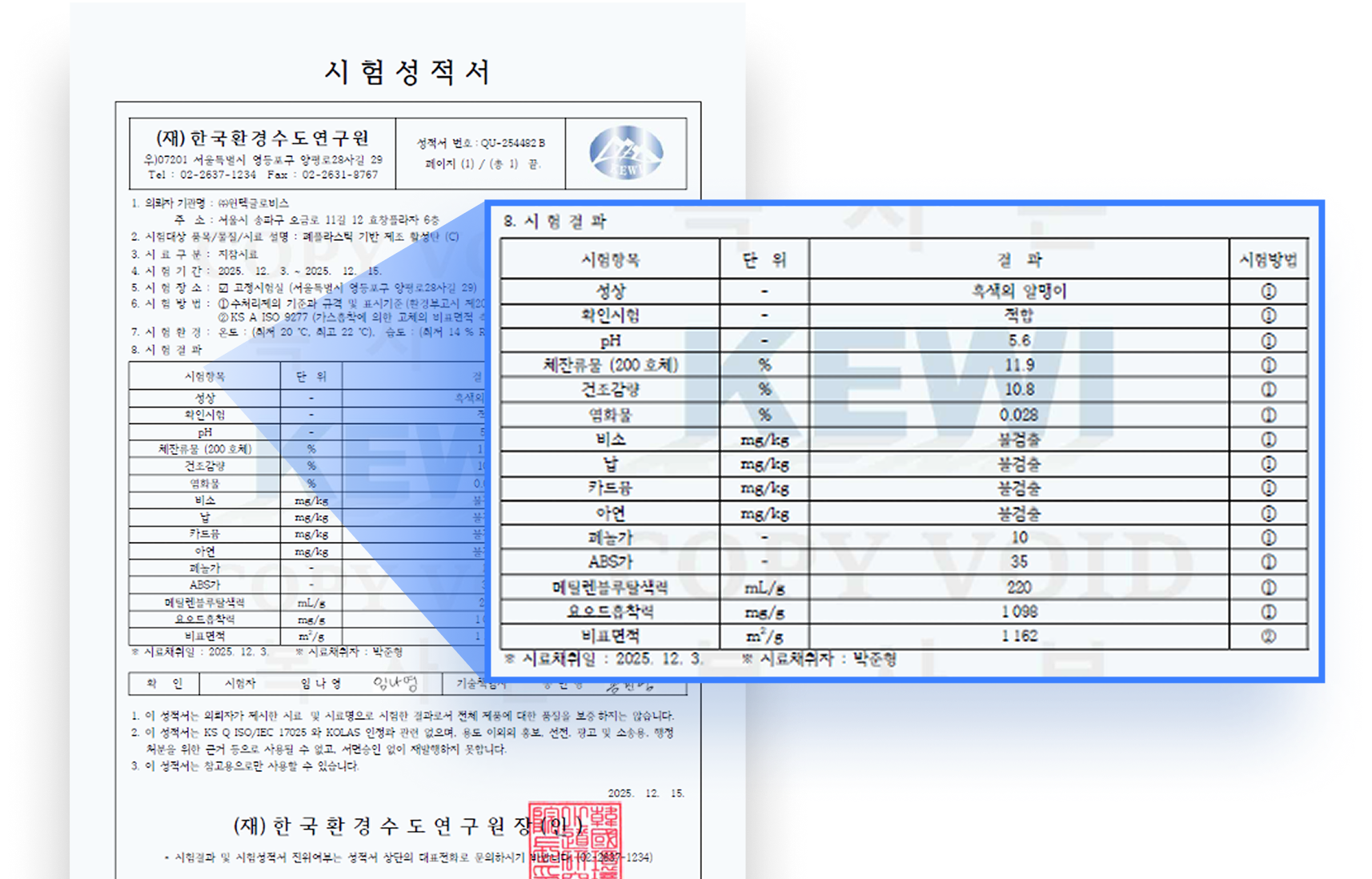

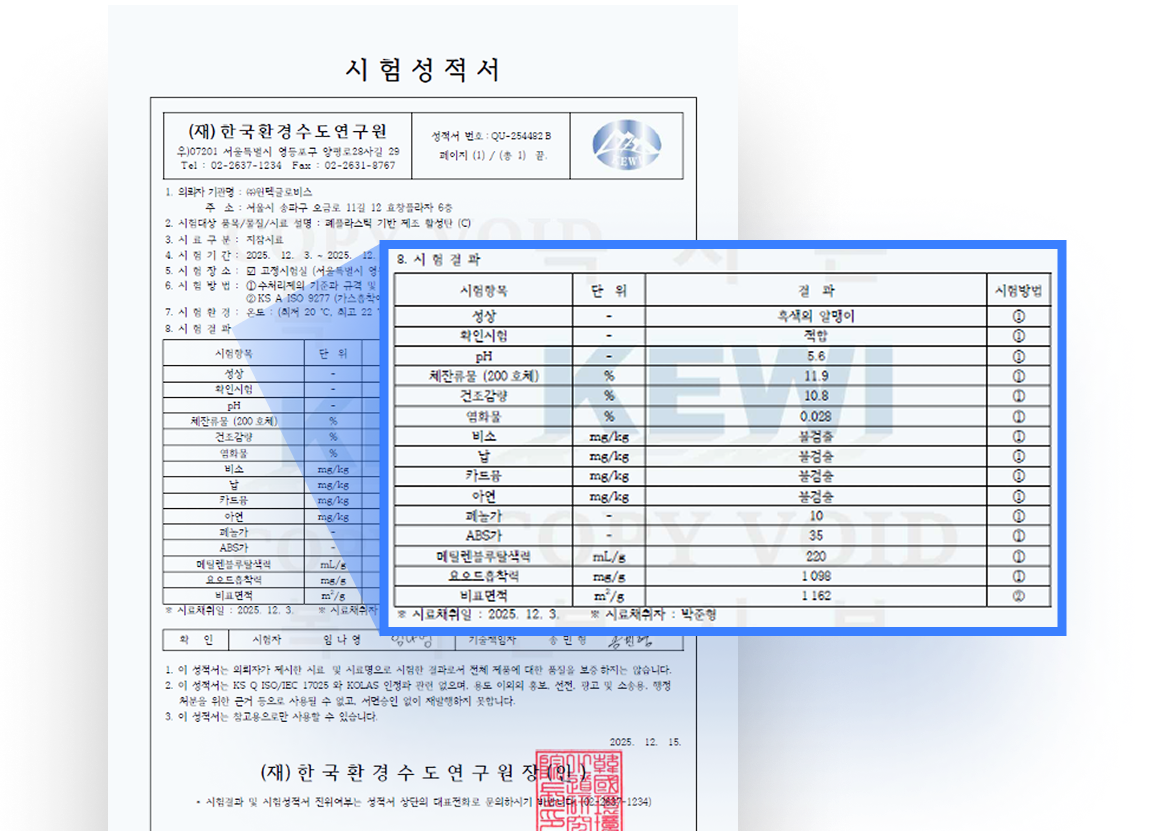

Meets 14 criteria under water-treatment agent standards, including a specific surface area of 1,098 m²/g and an iodine adsorption value of 1,162 mg/g.

- Eco-friendly activation manufacturing equipment using superheated steam

- Excellent production efficiency by improving thermal efficiency and minimizing changes in material properties through the superheated-steam process

- Enhanced facility safety through an oxygen-free process

- Manufacture of activated carbon capable of reliably removing taste, odor, organic matter, and PFAS, etc.

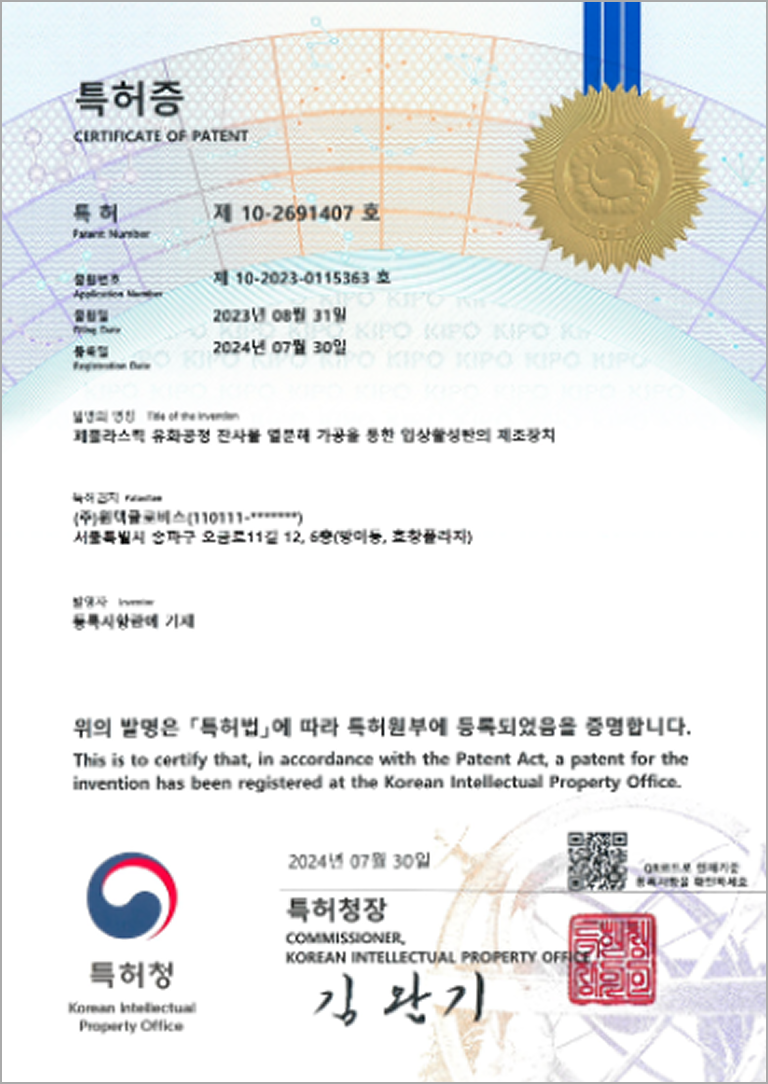

- Innovative, patented new technology for activated carbon manufacturing using superheated steam

Certified Test Report for Manufactured Powdered Activated Carbon

Related patents held

Activated Carbon Manufacturing Process

-

STEP 1

Providing

Precursor -

STEP 2

High-Temperature Activation Using

Superheated Steam -

STEP 3

Powdered Activated

Carbon (PAC) Production -

STEP 4

Granular Activated

Carbon (GAC) Production